WOVEN PP/PE CONTAINER LINERS

We have a wide range of designs of PE/PP woven container liners which is commonly

used in petrochemical industries, chemical industries and in many food grade applications. Woven

PP/PE Container Liners are the general liners used for the bulk transportation of materials

globally.

These liners come with generally two compositions woven polypropylene liners or woven

polyethylene liners. Container liners are generally available in 20’, 40’ and 40’ HC sizes. Apart

from this there are customized dimensions like 23’, 30’, 45’ and 54’ length liners according to

their container availability

STANDARD / MALT LINERS

These are general-purpose liners used as the most economic transportation

solution. It is commonly used in malt industries and other chemical industries where the

customer requires low value packaging medium with less handling cost for their bulk

transportation. The common filling and discharging options are.

Wide open zipper filling with conical discharge.

Filling support, discharge spout and ventilation support

These liners generally come with 240 X240 X590 cm dimension for 20’ liners and 240 X 240 X 1200

cm_ for 40’ GP containers and 240 X265 X1200 cm for 40’HC containers. Zipper panel filling is

used where the conveyor loading or belt thrower loading system is used for filling the liners.

Spouts with various diameter is used for pneumatic loading.

The discharging is done with gravity dumping or vacuum sucking. The discharging options will be

spouts, conical spouts, fish tail discharge and also triangular discharge. Apart from loading

and unloading, the liners come with other accessories like ventilation spout, inspection

windows, hanging points, bar sleeves, bar loops etc.

There are metal accessories used in some liners which is used for the ease of installation like

carabiner hooks, cam buckles, metal rings, metal braces etc..

BARLESS WOVEN LINERS

These are the premium container liners which are specifically designed to

eliminate the cost of metal bars. The Barless liners can be of liners with baffles or liners

without baffles. Liners without baffles are made with extra horizontal straps to protect the

cargo which are commonly used for transportation of coffee beans, rice, maize etc. Though these

liners are not the safest, they are more economical compared to baffled liners.

These liners come with 20’, 40’ and 40’ HC sizes. The normal dimension will be 240 X240 X575

cm for 20’ liners and 240 X240X1175 cm for 40’ liners. The loading, discharging and the other

accessories are common for standard and barless liners.

LDPE FILM CONTAINER LINERS

To be the customer’s obvious choice by providing total logistic solutions through

innovation and reliable services. And also developing intelligent supply chain solution and

delivering the highest level of service quality and efficiency.

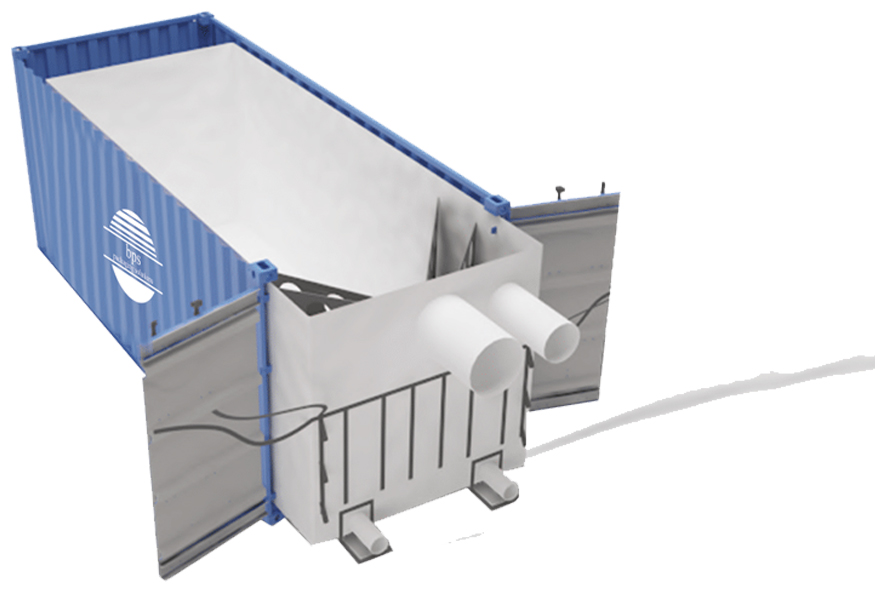

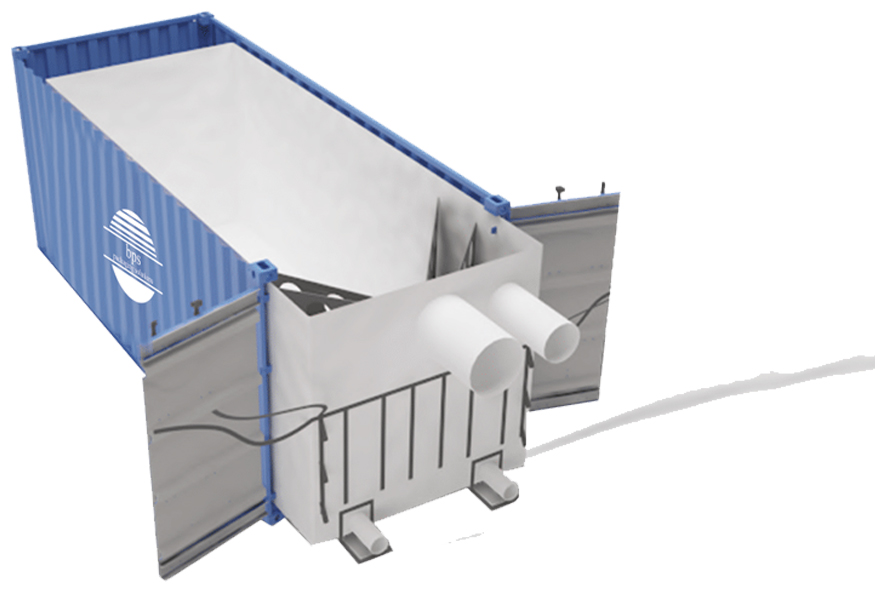

These are of more hygienic and moisture free bulk packaging solution which are generally

used for the packaging of specialty polymers, food grains, and for special chemicals. These

Liners come with the body of Polyethylene film and a bulk head of either polyethylene film or

polypropylene woven fabric. Due to its raw material characteristics, these liners are more

hygienic compared to woven liners. We are offering a special design to our customers for the

transportation of product which is hygroscopic in nature. Due to its character of absorbing the

moisture content from the atmosphere, these materials are very difficult to get discharged from

the container when it is loaded in bulk. So, we are offering a fluidizing pipe system along with

the liner to facilitate an extra pressure with compressed air fed through the pipes to have easy

discharge of material from the liner.

The size of these liners is also same as that of standard woven liners. The bulkhead for

these liners will be normally made of higher GSM PP fabric and sometimes with thicker PE film

also.

DRIVE IN LINERS

These are used for the transportation of hide, fish meals and other obnoxious or caustic commodities. These are generally standard liners with open top designs. These are normally low-cost liners and are used to protect the hygiene of the containers. These liners come with 20’ and 40’ dimension. The wall height of the liner will be full height, half height or sometimes 3/4” height of the container.

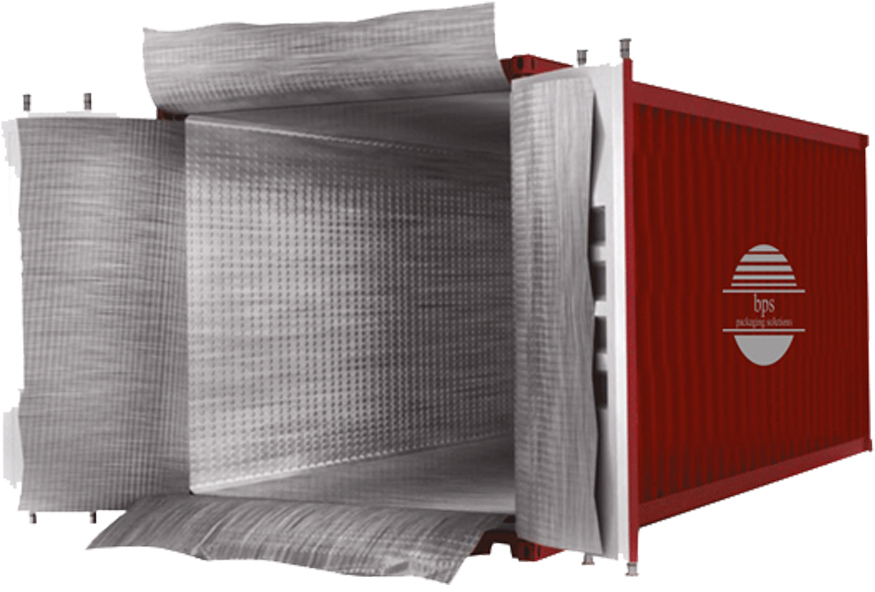

THERMAL LINERS

These are the liners made of barrier laminates. Normally these laminates are of 5 layers or 3 layers and the outer layer will be of aluminium foils. These liners are mostly used for packaging and transportation of such products which are sensitive to temperature variations for example fruit pulps, wine etc... As the liners are made of aluminium foil laminates which are thermal barriers, this will maintain the inside temperature fluctuation within 3 degree Celsius These liners come with 20’, 40, and 40’ HC sizes.